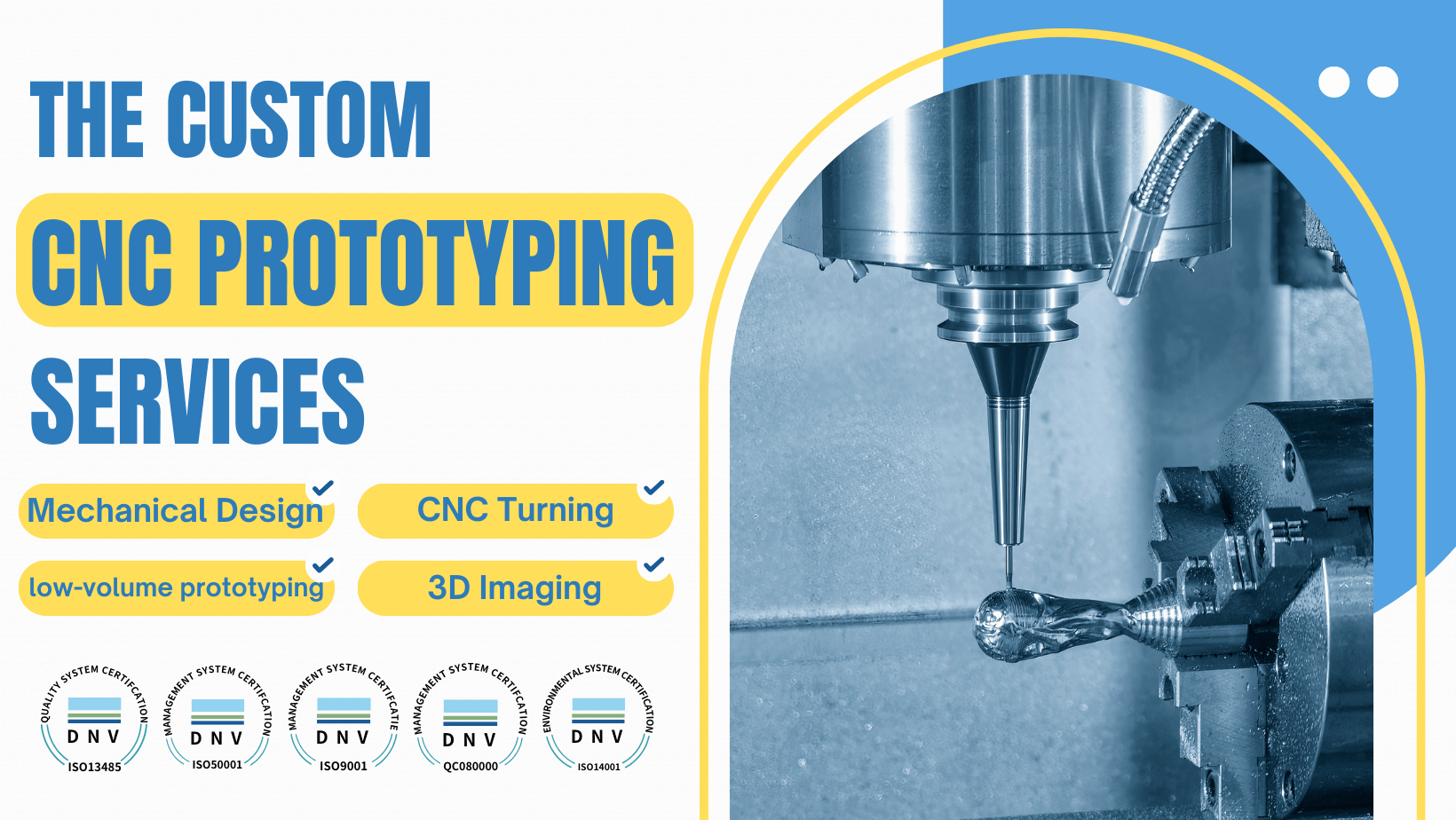

The Custom CNC Prototyping Services

In any product development cycle—whether in consumer electronics, automotive parts, medical devices, or industrial machinery—prototyping is a critical stage that bridges conceptual design and mass production. While Computer Numerical Control (CNC) machines excel at mass-producing precision parts, ensuring high tolerances, repeatability, and speed, it’s unwise to move directly into large-volume manufacturing without first testing a prototype. A prototype serves as a tangible representation of your design, allowing your team to assess factors such as dimensional accuracy, assembly fit, cosmetic finishes, and real-world functionality.

Why Do We Need Prototypes?

Here are the key reasons why investing in a prototype can save you time, money, and headaches further down the line:

-

Validation of Design and Fit

Even the most carefully developed 3D models and simulations can’t fully capture the tangible nuances of a physical part. Prototypes confirm whether parts fit together correctly, reveal potential interference issues, or highlight ergonomic flaws that may not be obvious on-screen. -

Quality and Reliability Checks

The hallmark of CNC machining is its high degree of precision. But “precision” is only meaningful if the part satisfies the functional requirements. A prototype highlights how material choices (e.g., aluminum vs. stainless steel vs. engineering plastics) influence structural integrity, heat dissipation, or corrosion resistance. -

Reduced Overall Cost

Although prototyping adds an initial investment, it is far more cost-effective than discovering a critical flaw mid-production. A single prototype run can reveal areas to cut down on material usage, shorten machining cycles, or adjust tolerances before ordering thousands—or millions—of parts. -

Stakeholder Buy-In and Presentation

Physical prototypes strengthen pitches to investors, stakeholders, or customers. A tangible model can demonstrate the value and viability of a product in ways that digital renderings cannot.

At Chienfu, we understand the pressures modern businesses face: time-to-market expectations, budget constraints, and the quest for innovation. That’s why we offer Custom CNC Prototyping Services that balance speed, quality, and cost-effectiveness, ensuring you get the best result for your preliminary design tests before scaling up.

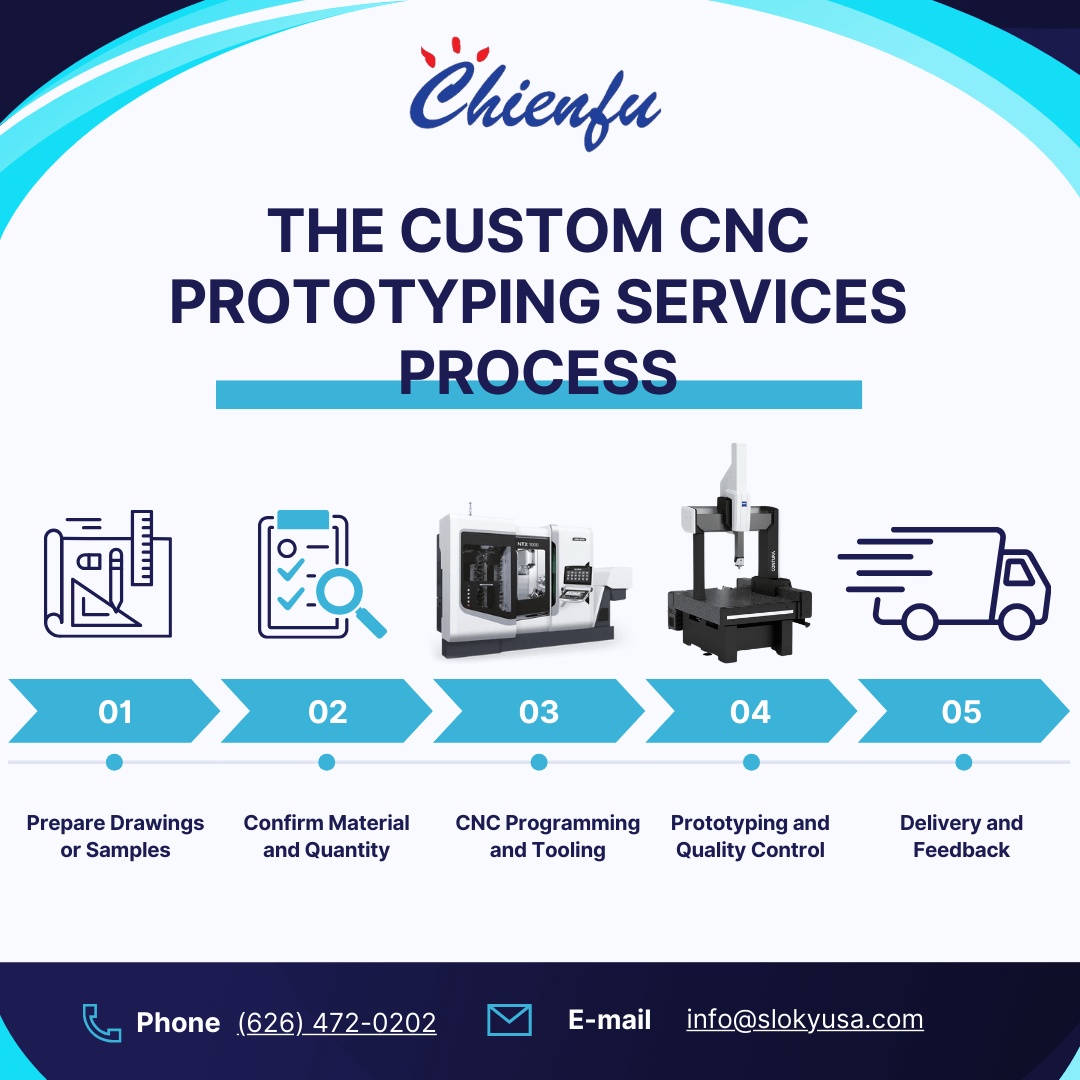

Prototyping Services Process

Every successful prototype begins with clear communication and well-prepared documentation. At Chienfu, we streamline the entire process—from your initial inquiry to final delivery—so your team can stay focused on product development. Below is an overview of our standard workflow:

-

Prepare Drawings or Samples

We recommend providing detailed 2D/3D drawings to capture dimensions, tolerances, and critical features. If your design is still evolving, or if you only have a physical sample, we can replicate that sample through reverse engineering, 3D scanning, or direct measurement.- No Files? In such cases, please coordinate with your in-house R&D or procurement department to supply a competitor’s part or a reference sample, giving us a tangible foundation for your prototype.

-

Confirm Material and Quantity

Our technical team will consult with you to choose an appropriate material—be it aluminum, steel, titanium, or engineering plastics—depending on the functional, cosmetic, and cost considerations of your project. We’ll also define the desired quantity for the prototype run, any post-processing (anodizing, plating, polishing, etc.), and packaging/shipping specifications. -

Online Consultation or Fax Inquiry

After you submit drawings or samples, our engineering experts will review every detail. We’ll reach out to confirm design features, clarify tolerances, and solidify any special requests. During this phase, we might suggest alternative manufacturing methods or material substitutions if we see opportunities to reduce cost (cost down) or enhance performance. -

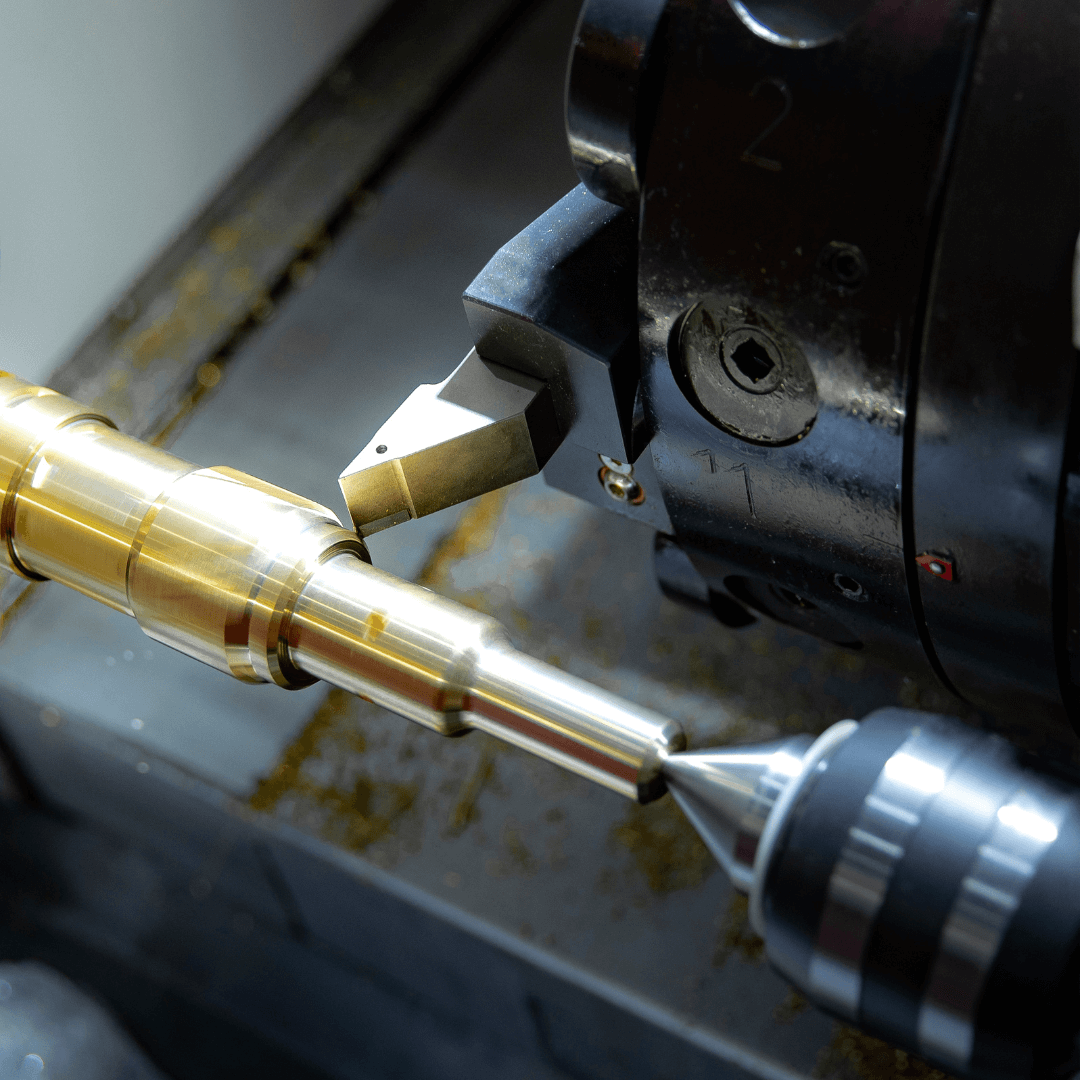

CNC Programming and Tooling

Once all the details are finalized, our CNC programmers create toolpaths suited to your unique design. We consider factors like chip evacuation, tool access, speed/feed rates, and coolant usage to ensure both an efficient run and a surface finish that meets your requirements. -

Prototyping and Quality Control

Our CNC machines produce each prototype according to the approved design. Throughout the machining process, we perform in-process inspections, measuring critical dimensions via coordinate measuring machines (CMMs) and other precision instruments. We also confirm the part’s consistency, tolerances, and finishes before finalizing your prototypes. -

Delivery and Feedback

This Custom CNC Prototyping Services process was designed to be both flexible and robust, enabling us to handle single-part runs or small-batch orders with equal efficiency. Whether you’re developing a new consumer gadget or a complex aerospace component, our approach ensures that your prototype is produced accurately, swiftly, and with minimal hassle.

How to Choose a CNC Prototyping Services Partner

Selecting the right CNC manufacturer for your prototyping project can significantly influence your product’s success, both in the short term (design validation) and long term (scaling to mass production). Below are some criteria to keep in mind:

Look for End-to-End Services

Prototyping often involves more than just machining a single part. You may need raw material procurement, additional post-processing (e.g., anodizing, plating, polishing), thorough inspections, and even logistics support to ship your parts globally. An all-in-one CNC shop that provides “turnkey” or “one-stop” solutions can save you time, reduce the risk of errors, and simplify your supply chain. At Chienfu, we provide:

- Raw Material Management: We source and verify metals, plastics, and exotic alloys, all stored in controlled environments.

- Precision Turning and Milling: Our CNC machines handle complex geometries and tight tolerances efficiently.

- Post-Processing: From surface treatments to secondary operations like tapping or thread rolling.

- Quality Inspection: In-house measurements and testing protocols ensure prototypes meet exact specifications.

- Shipping and Logistics: We arrange safe packaging, coordinate global shipping, and manage documentation.

Seek a Manufacturer with Design Capabilities

In the prototyping stage, your ideas may still be evolving. A CNC supplier that offers design-for-manufacturability (DFM) consulting or engineering support is invaluable. They can evaluate your design, suggest alternative materials, or recommend less labor-intensive machining operations. This not only lowers cost but often improves the final product’s performance, durability, or cosmetic appeal.

Modern CNC technology evolves constantly, providing new ways to achieve the same features faster and more economically. A forward-thinking shop can point you toward the newest machining strategies—like multi-axis simultaneous milling or combined turning-and-milling centers—that streamline production and reduce cycle times.

Communication and Local Presence in the U.S.

Prototyping is an iterative process. Expect multiple rounds of feedback, design tweaks, and engineering discussions. If your supplier isn’t readily accessible, you may face communication hurdles that introduce delays or misinterpretations. Ideally, your chosen CNC partner should have a U.S.-based contact or office to handle time-sensitive requests, clarify specifications, and expedite shipping. This is particularly helpful when design changes occur rapidly, or you need daily updates on your prototype’s progress.

At Chienfu, we take communication seriously. Our local U.S. representatives are available during American business hours to ensure that no question goes unanswered, no deadline is missed, and no design detail is overlooked.

Why Choose Chienfu for CNC Prototyping Services

Chienfu combines decades of CNC expertise with a customer-centric approach that makes us a reliable partner for businesses in various industries, including medical, automotive, aerospace, consumer electronics, and industrial automation. Here’s what sets us apart:

-

Holistic Project Management

-

Cutting-Edge CNC Equipment

-

Compliance with International Standards

-

Design and Engineering Support

-

Global Network, Localized Service

-

Scalable Solutions