How to Choose a Medical Components Manufacturing Partner?

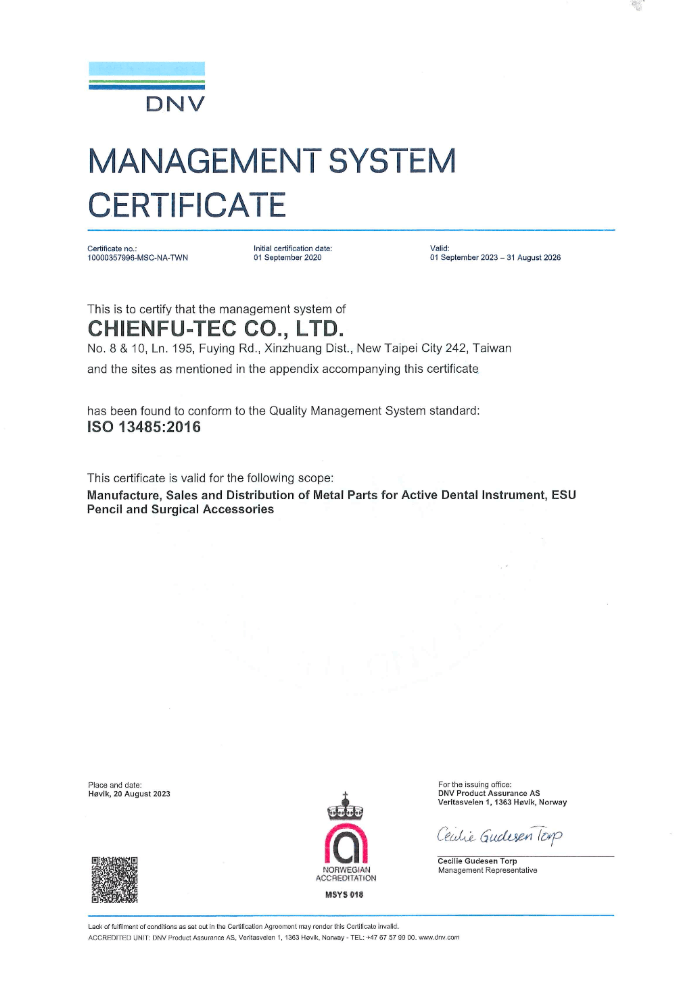

In today’s competitive medical device market, quality and safety are paramount. Manufacturing partners for medical components play a critical role in the overall performance of a product. For R&D and procurement managers, selecting a partner with authoritative certifications and advanced machining technology is key to mitigating risks and ensuring product excellence. ChienFu stands out with its ISO 13485 and ISO9001 certifications—and additional environmental certifications such as ISO50001, ISO14067, and ISO14001—offering secure and reliable medical components manufacturing services.

Certification Requirements for Medical Components Manufacturing Partner

Certifications are essential to guarantee the safety and quality of medical components. ChienFu not only meets the rigorous standards of ISO 13485—specifically designed for medical devices—but also adheres to the ISO9001 quality management system. These certifications ensure that every stage of the production process meets strict international standards. Additionally, ChienFu’s environmental certifications (ISO50001, ISO14067, and ISO14001) highlight its commitment to sustainable manufacturing practices. These credentials give procurement managers the confidence that every batch produced adheres to the highest medical standards.

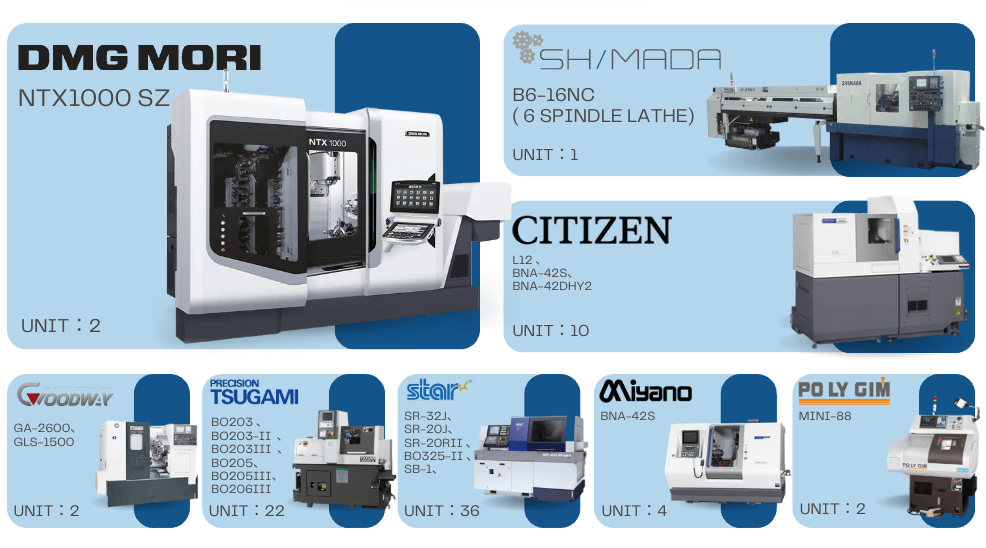

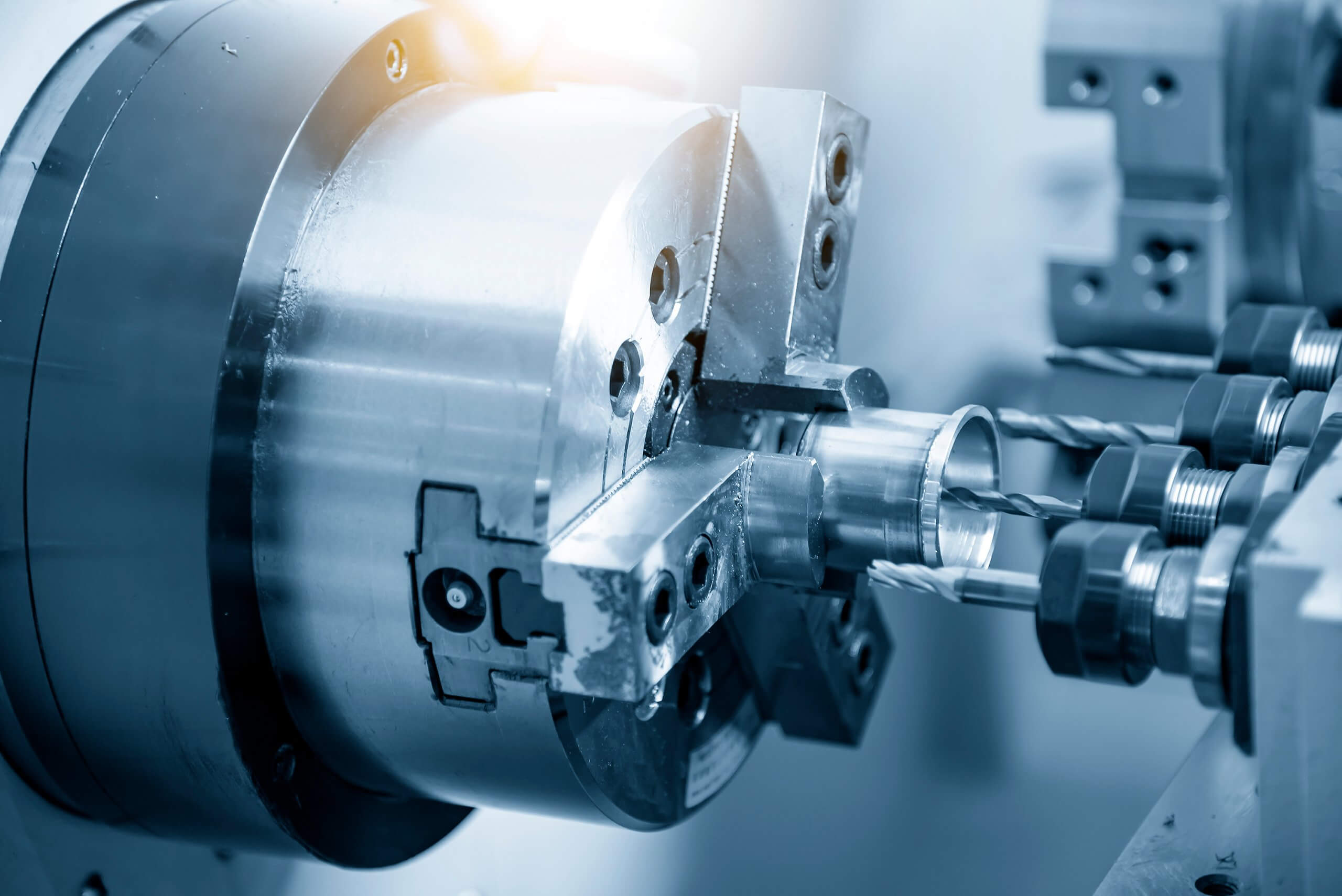

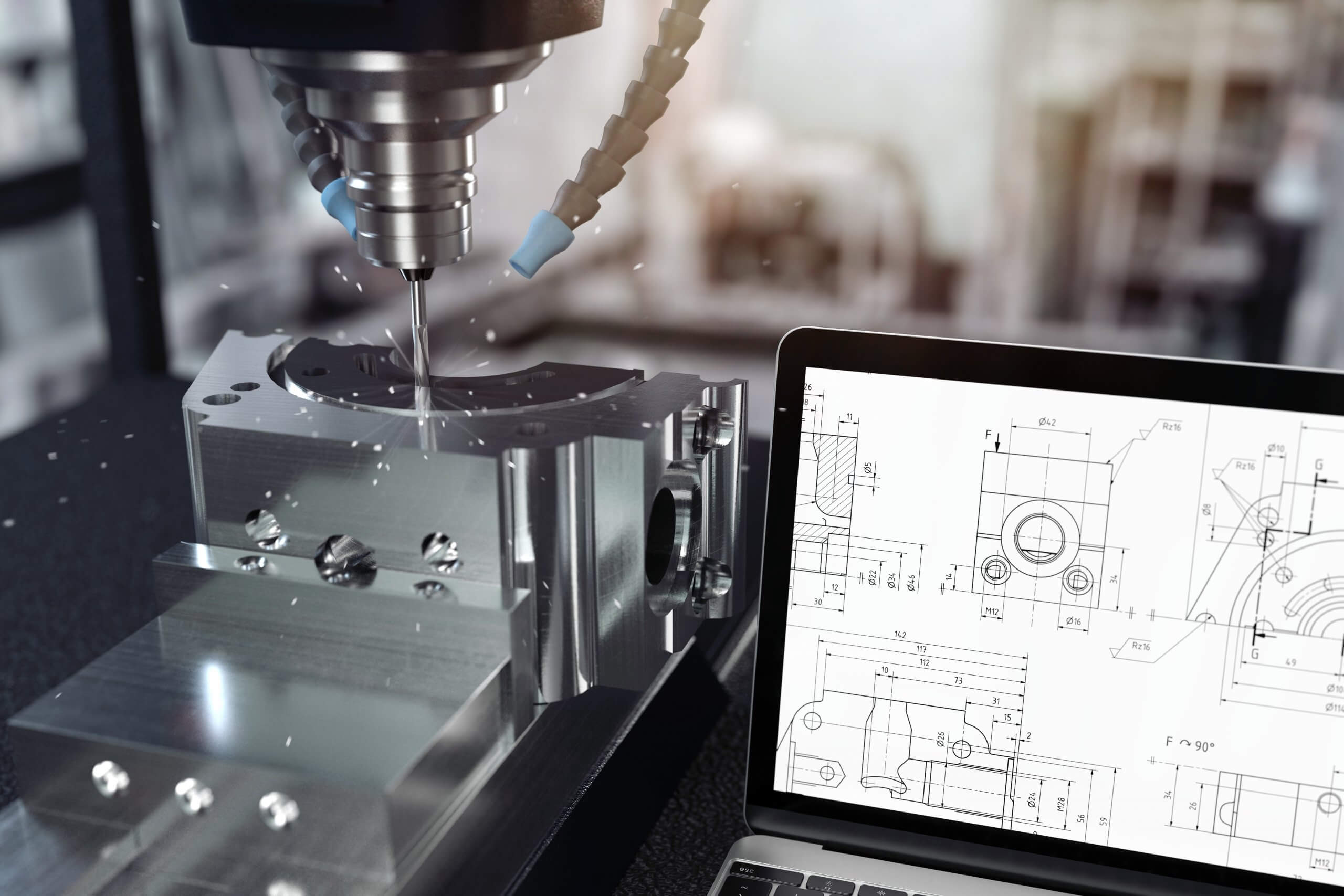

Application of Advanced Technologies in Manufacturing

Cutting-edge CNC machining and multi-metal processing are at the core of ensuring the precision and consistency of medical components. ChienFu employs state-of-the-art CNC equipment capable of handling a variety of metals—including stainless steel and titanium—ensuring that every component meets stringent medical design specifications. With automated inspection systems and digital process controls, ChienFu minimizes errors and boosts efficiency, ensuring consistent, high-quality output that meets the demanding requirements of medical applications.

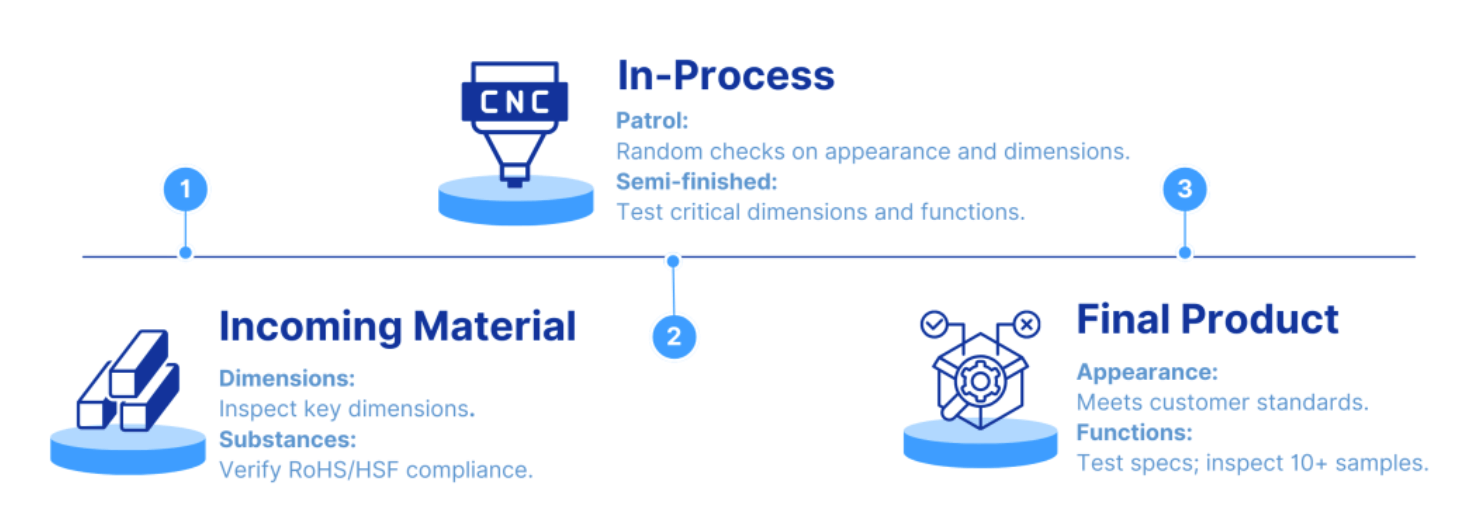

Evaluating Supplier Capabilities and Production Processes

When choosing a manufacturing partner for medical components, it is crucial to assess their production processes and quality control measures. Procurement managers are advised to visit the facilities, review raw material inspections, and scrutinize every stage from component manufacturing to final quality checks. ChienFu offers comprehensive production tracking and detailed quality reports, ensuring transparency across all processes.

Comparative Analysis and Selection Strategies

Integrating certifications and advanced technology is key when evaluating potential manufacturing partners. R&D and procurement managers should compare suppliers based on their certifications, technological capabilities, production processes, and client success stories. If you are looking for a partner that not only holds respected certifications but also leverages advanced machining technology to deliver precise, reliable components, ChienFu is your ideal choice. Contact ChienFu today and let us support you in producing high-quality, dependable medical products!

If you’re looking for a manufacturing partner with authoritative certifications and state-of-the-art CNC machining capabilities for your medical components, contact ChienFu today. Let us be the reliable backbone for your medical device production, and together, we can achieve unparalleled product quality!