A Comprehensive Buyer’s Guide to CNC Machining for Aerospace

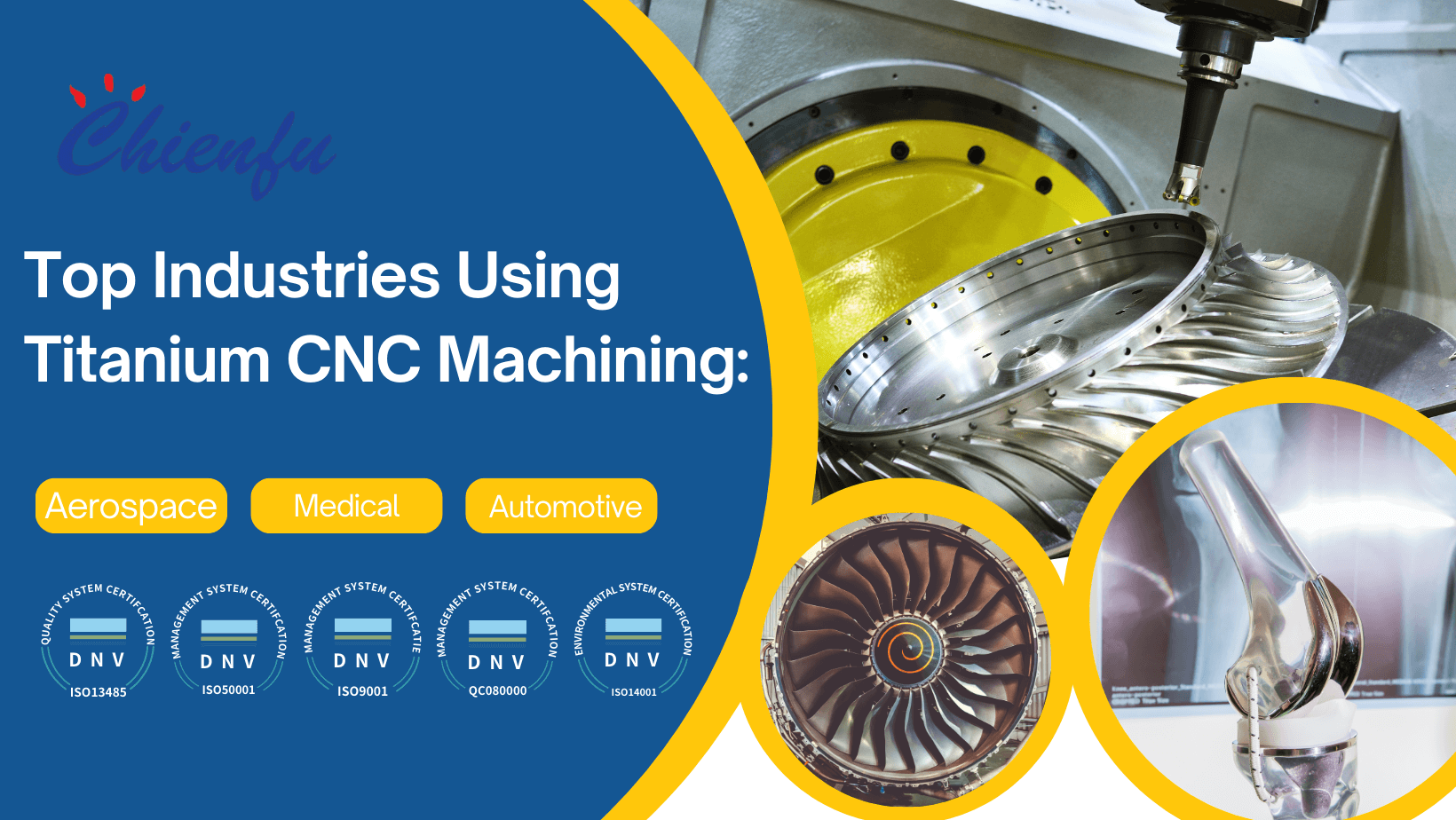

Aerospace components must perform flawlessly under extreme conditions, from high-speed flight to rapid temperature shifts. That’s why CNC machining for aerospace has become essential for achieving the unmatched precision and reliability this sector demands. Titanium, in particular, stands out for its superb strength-to-weight ratio, but it’s also notoriously difficult to machine. Computer Numerical Control (CNC) technology, coupled with advanced tooling, makes it possible to craft these critical parts with near-microscopic tolerances.

Why CNC Machining Is So Important in Aerospace

Aerospace demands parts that withstand extreme forces, temperature shifts, and vibrations. Unlike traditional methods, CNC machining uses digital instructions to produce complex parts at micron-level precision—even in large runs. This consistency is critical for fleets that rely on uniform, high-quality components.

-

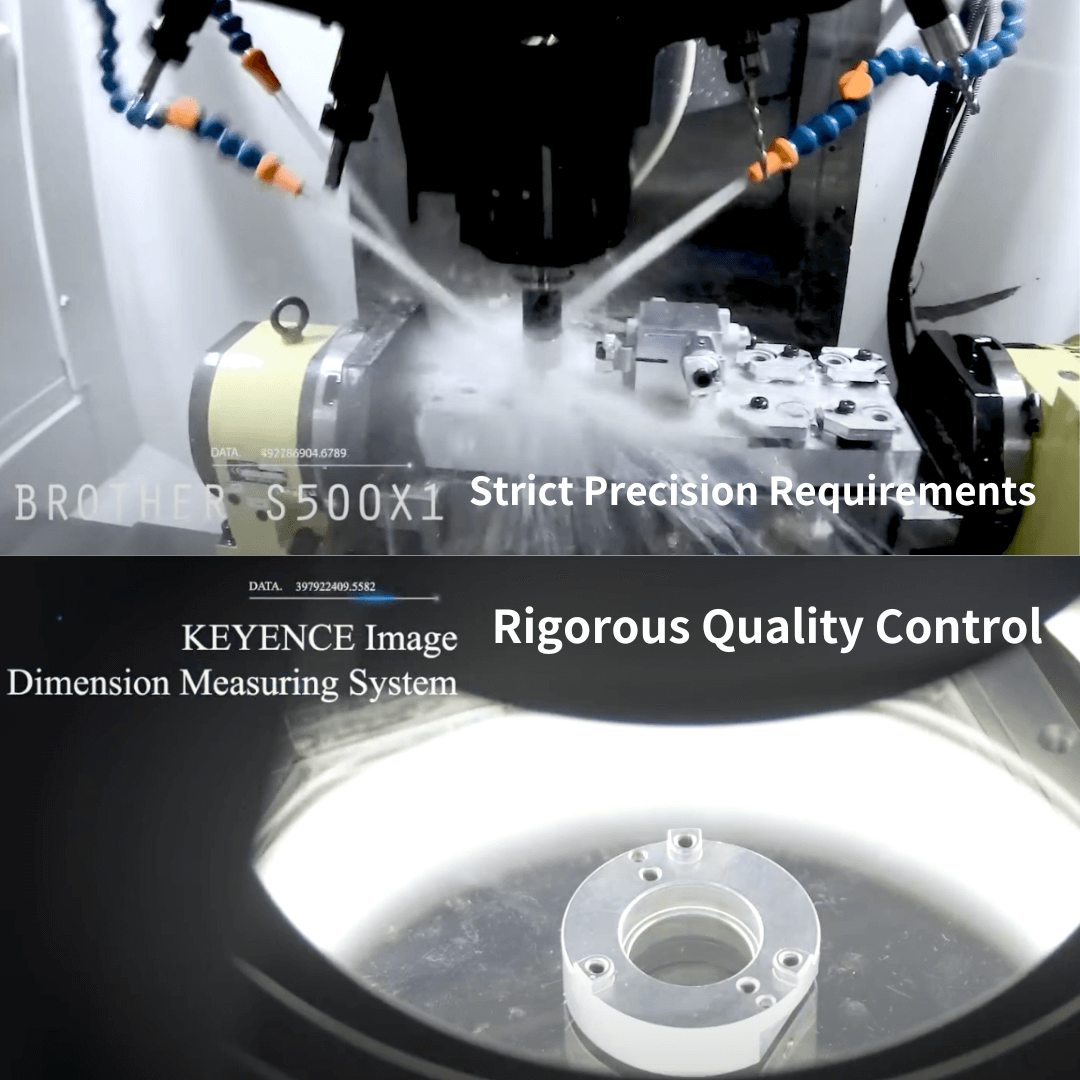

Strict Precision Requirements

A minor misalignment can lead to dangerous mechanical failures. CNC automation minimizes errors by constantly adjusting for tool wear, ensuring parts fit exactly and maintain full structural integrity. -

Efficiency and Consistency

Aerospace programs often move from prototypes to large-scale production. CNC’s programmable design simplifies this transition without compromising accuracy, delivering a seamless response to changing project demands. -

Batch Production and Repeatability

Once a CNC program is optimized, it repeatedly yields parts with the same tight tolerances. This reliable uniformity removes manual errors and helps every component meet critical specifications. -

Rigorous Quality Control

Aerospace standards require thorough traceability and documentation. Leading CNC shops use advanced inspection tools—such as coordinate measuring machines (CMMs)—to confirm precise tolerances. This disciplined approach ensures flight-ready components and boosts overall safety.

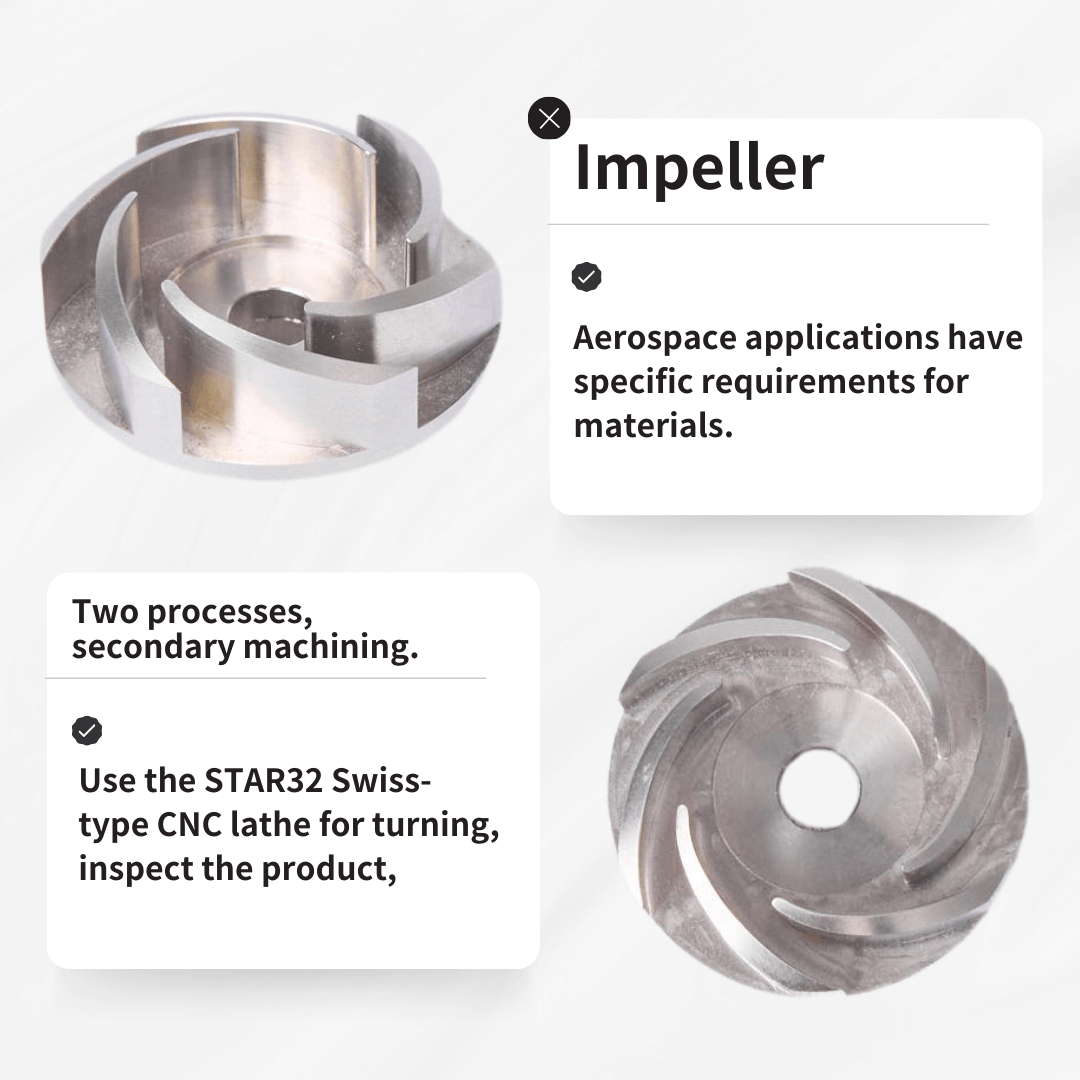

Aerospace CNC Machining Materials

The aerospace industry imposes strict requirements for materials, often balancing high strength with minimal weight. With advanced tooling and precision control, CNC technology can effectively process specialized metals and composites to meet these demanding standards.

-

Aluminum Alloys:

Lightweight, corrosion-resistant, and relatively easy to machine—ideal for aircraft skins and support structures. -

Titanium and Superalloys:

Highly durable under extreme heat and stress but challenging to machine. Specialized cutting fluids and optimized speeds are essential for maintaining precision. -

Composite Materials:

Carbon fiber or other fiber-reinforced polymers excel in stiffness and fatigue resistance. However, they require careful machining parameters to prevent delamination or fiber damage.

How to Choose a CNC Machining Partner

Multi-Axis Machining

Aerospace parts often feature complex geometries—angled cavities, undercuts, and curved surfaces. Multi-axis machining (such as 5-axis milling) allows fabricators to reach these features in fewer setups. This level of control enables precise, efficient machining of intricate parts.

Turn-Mill Complex Machinery

Combining lathe and milling functions into one platform reduces part handling and boosts accuracy. Turn-mill machines handle both rotational and prismatic features in one setup, minimizing alignment errors and ultimately shortening production timelines.

Surface Treatment

In harsh aerospace environments, surface treatments like anodizing, passivation, and specialized coatings can be essential. A CNC provider that offers in-house or well-managed outsourced finishing services ensures parts meet corrosion resistance and aesthetic standards without unnecessary shipping delays.

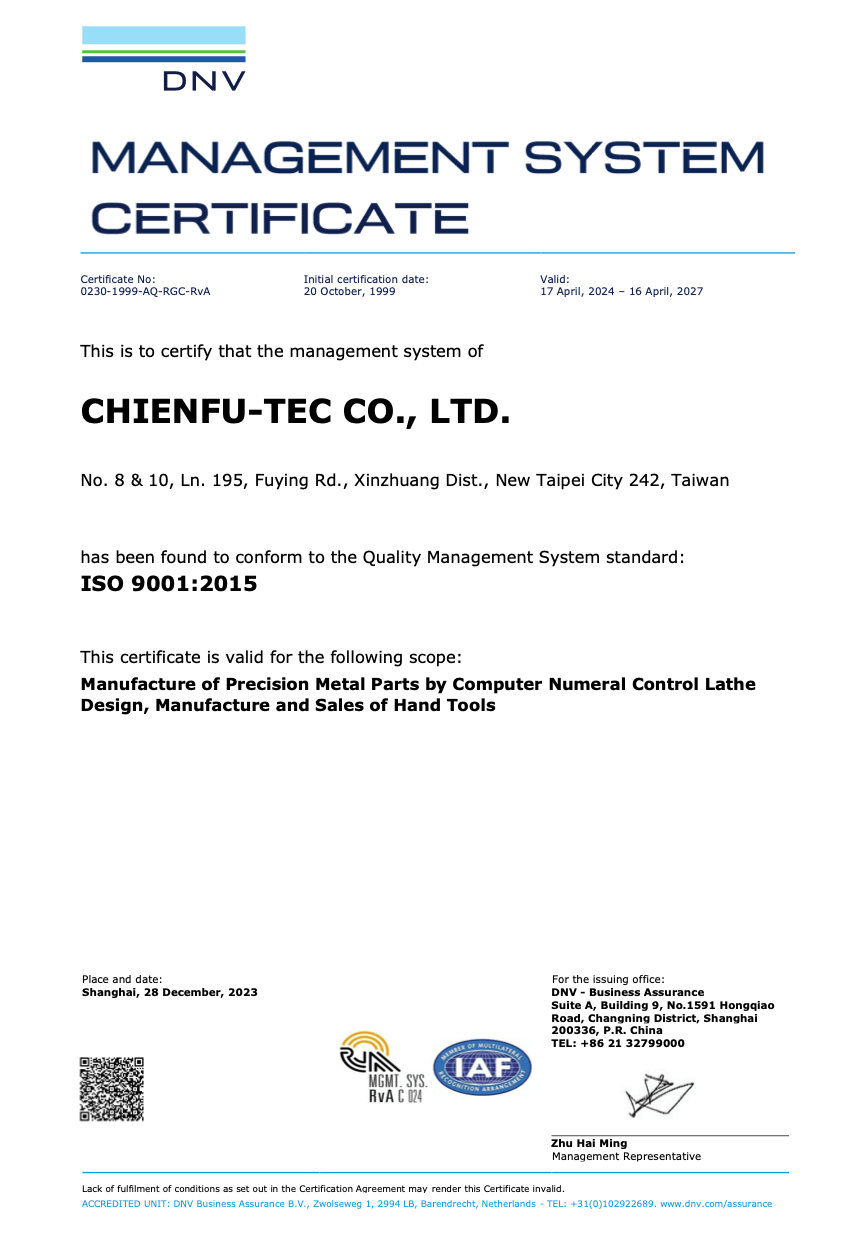

Inspection and Testing

Compliance with ISO9001 or aerospace-specific certifications (e.g., AS9100) is a strong indicator of reliability and thorough documentation.

The Chienfu Advantage

Extensive Machine Fleet

With 150 CNC machines, we are well-prepared for projects ranging from small prototypes to large production runs. We pride ourselves on short lead times and high production capacity to meet demanding schedules.

DMG Turn-Mill Expertise

Our DMG turn-mill complex machinery merges multiple processes into a single setup. This integrated method reduces tool changes, preserves alignment, and speeds up manufacturing. Clients benefit from faster turnaround and top-notch dimensional accuracy.

Surface Treatment and Quality Control

We support essential surface finishing processes—such as anodizing, passivation, and polishing—to protect components against corrosion and wear. Our inspection equipment, including three-dimensional (3D) measuring machines, ensures every dimension meets strict aerospace requirements.

Moreover, we adhere to ISO9001 standards, underscoring our commitment to systematic, traceable manufacturing. Each phase of production, from material sourcing to final inspection, is carefully monitored to guarantee consistent quality.

Ask Us A Question