What Is a Swiss Screw Machine?

Swiss screw machines originated in Switzerland to craft watch components and have since evolved into versatile equipment for numerous industries—particularly those where precision, repeatability, and complexity are paramount. By combining turning, drilling, milling, and other processes in a single setup, Swiss screw machines minimize secondary operations, accelerate production, and ensure consistent quality across high-volume runs.

Applications for Swiss Screw Parts

Swiss screw machining excels in producing small, detailed components at scale. From bone screws to aerospace connectors, these swiss machine parts are indispensable in industries where consistency and high accuracy are non-negotiable. Below, we highlight key application areas:

Medical Components

The medical device industry operates under stringent regulatory requirements, demanding zero compromises on quality or safety. Parts must be bio-compatible, exhibit perfect fit, and demonstrate long-term reliability. Custom Swiss Screw Machine Part solutions are ideal for:

- Implantable Bone and Dental Screws

Made from materials like titanium or stainless steel, these screws require precise threading and consistent dimensional accuracy to integrate seamlessly within the human body. - Surgical Instruments

Tools such as forceps, retractors, and specialized surgical devices often depend on micro-components that must maintain their integrity under repeated sterilization cycles. - Diagnostic Equipment

Medical equipment housings, fluid-control valves, and sensor components rely on tight tolerances for accurate measurements and dependable operation.

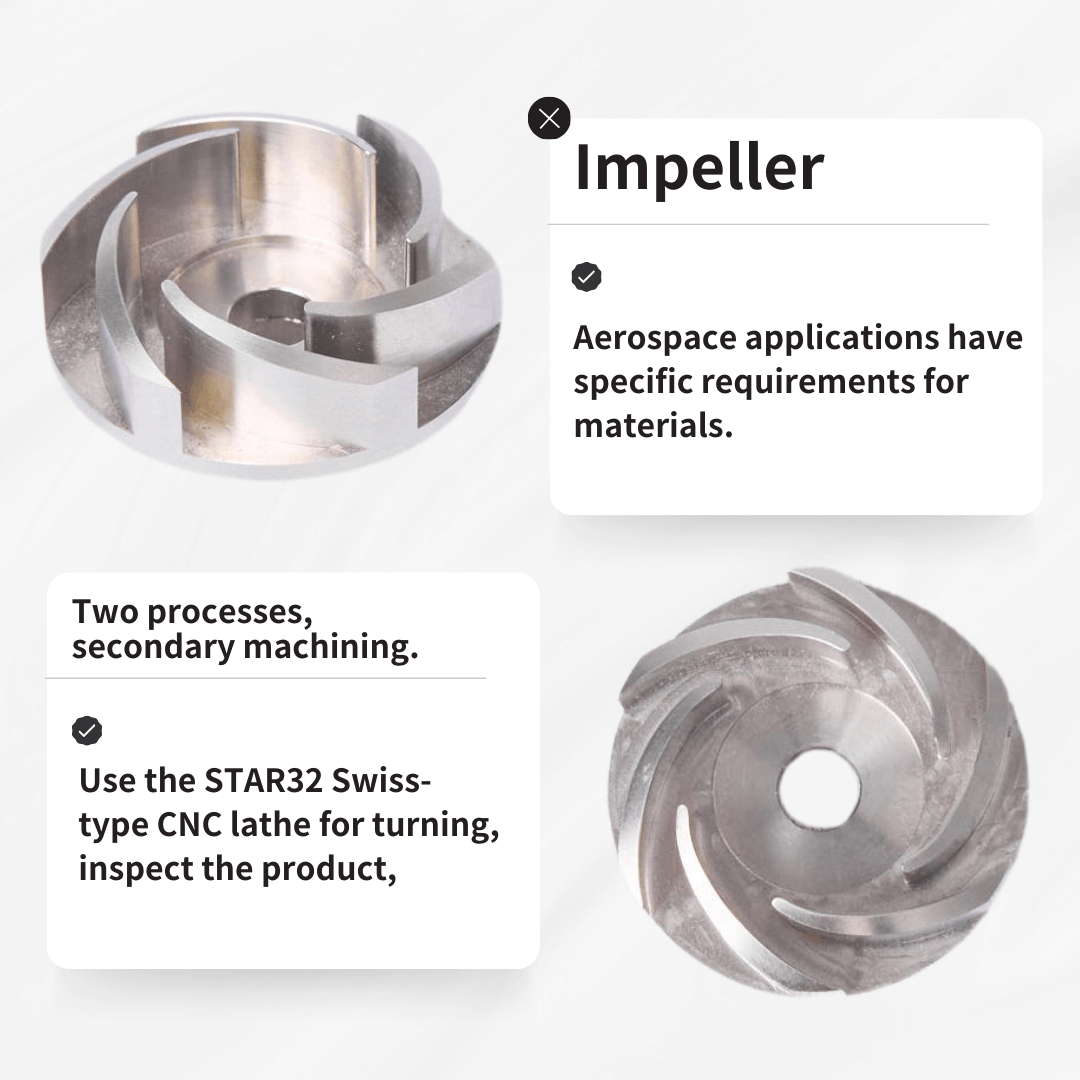

Aerospace Equipment

Aerospace parts endure extreme conditions, from large temperature fluctuations to intense vibrations. Weight, strength, and high-tolerance assemblies are paramount. Swiss machine parts used in aerospace include:

- Connectors and Fasteners: Designed to handle harsh environmental conditions and maintain secure connections in flight.

- Engine and Turbine Components: Small shafts, valves, and specialized fittings that must operate flawlessly at high speeds and pressures.

Automotive Parts

The automotive sector constantly seeks to improve performance, reduce emissions, and enhance safety—factors that depend on precision-engineered components. Swiss screw machining supports:

- Transmission and Powertrain: Shafts, gears, and fittings that function under continuous mechanical stress.

3C Electronics

In the world of computers, communications, and consumer electronics (the “3C” sector), device miniaturization and precision are crucial. Swiss machine parts address these needs with:

- Micro-Connectors: Essential for smartphones, tablets, and wearables that demand flawless electrical connections in tight spaces.

- Camera Lens Housings: Requiring immaculate surface finishes to secure lens elements and reduce optical aberrations.

- Actuator and Sensor Components: Enclosures and pivot points with exact alignments to preserve device functionality.

Automation Equipment

Automated systems rely on precision and durability to minimize downtime. Whether you’re developing robotic arms, conveyors, or specialized assembly stations:

- Drive Shafts and Pins: Must ensure minimal runout for smooth, reliable movement.

- Couplers and Fittings: Essential to create tight seals in pneumatic or hydraulic assemblies, preventing leaks and maintaining force control.

- Sensor Mounts: Guarantee stable positioning and alignment so sensors read accurately under dynamic conditions.

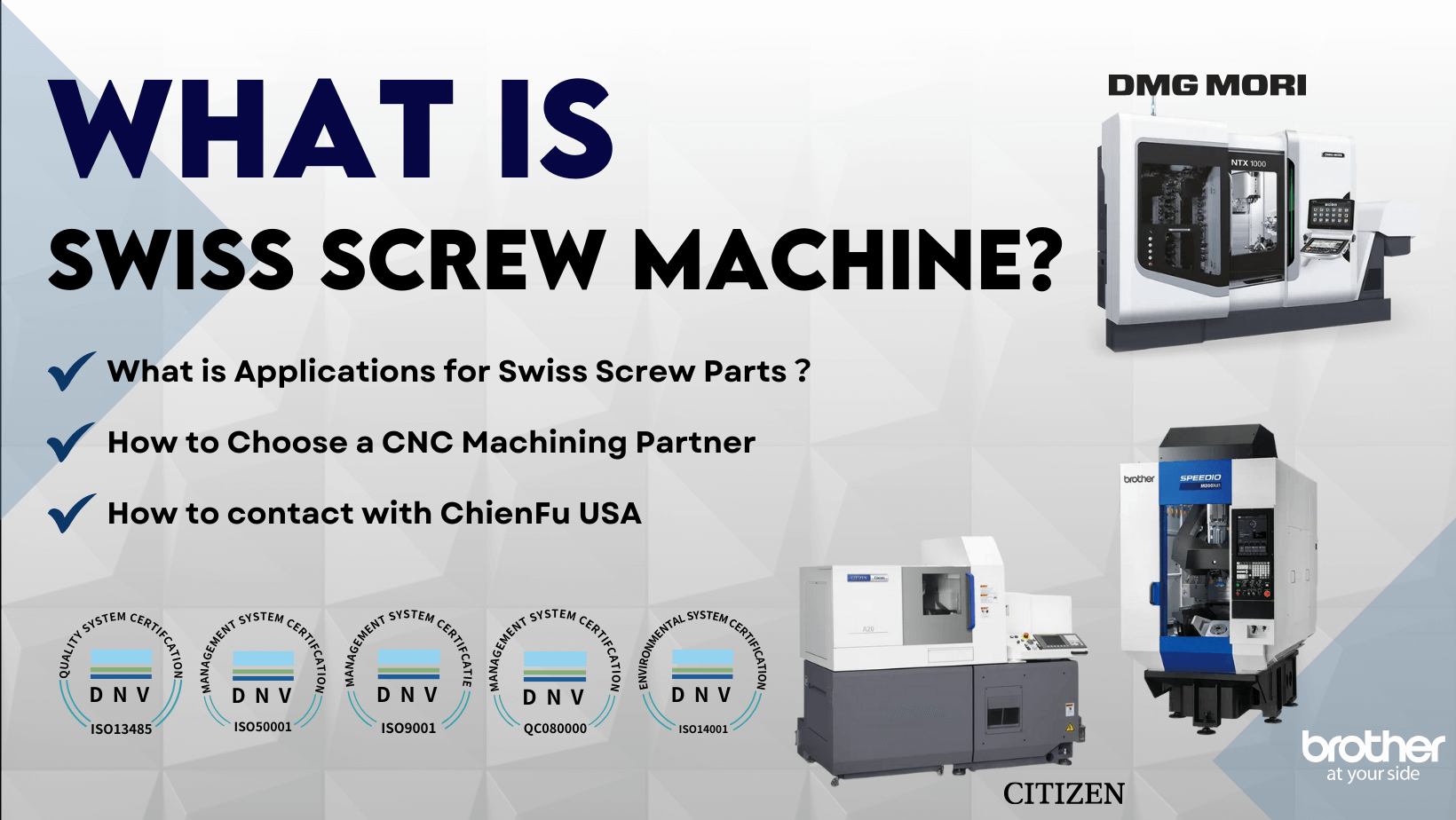

How to Choose a CNC Machining Partner

Partnering with the right CNC machining provider can make or break your project’s success. Below are critical factors to help guide your decision:

Certifications and Quality Management

Quality certifications are a window into a manufacturer’s reliability and commitment to process control. At Chienfu, we maintain:

- ISO 9001: Demonstrates our robust quality management system and commitment to continuous improvement.

- ISO 13485: Focuses on meeting stringent standards for medical device manufacturing.

- ISO 14001: Highlights our dedication to environmental management and sustainability.

- QC080000: Addresses hazardous substance process management, ensuring safer, eco-friendly production.

Each certification involves rigorous audits and ongoing compliance checks, ensuring that every Custom Swiss Screw Machine Part we produce aligns with internationally recognized standards.

Advanced Equipment and Technical Expertise

Not all machine shops are created equal. Swiss screw machining demands specialized equipment and skilled operators. Key points include:

- State-of-the-Art Swiss-Style Machines: Multi-axis lathes and milling centers capable of simultaneous operations.

- Automation : Enables continuous production for large-volume orders, reducing per-part costs.

- Tool Monitoring Systems: Automatic detection of tool wear ensures every part meets tolerance requirements.

- Process Control Software: Seamless integration of CAD/CAM, statistical process control (SPC), and real-time monitoring.

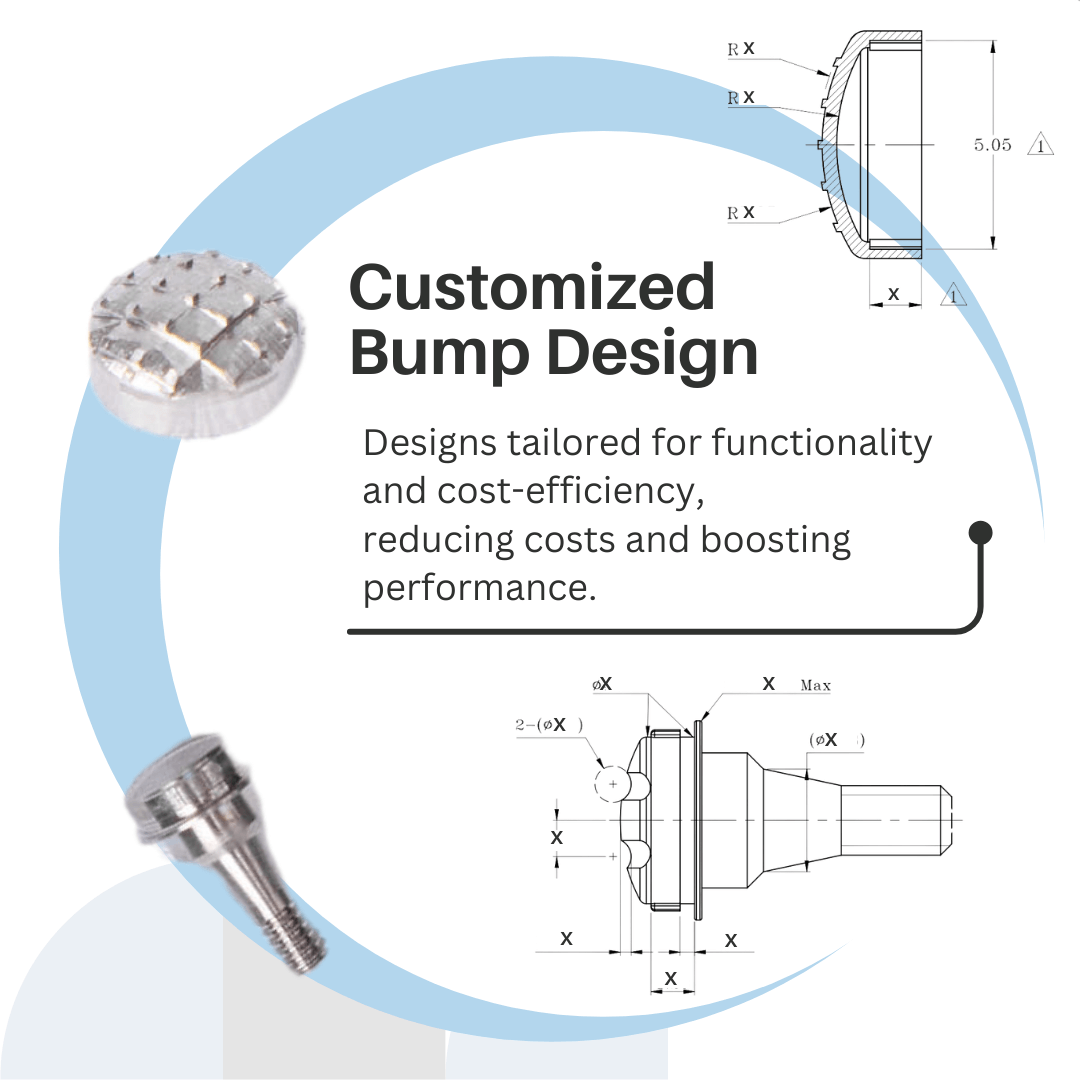

Engineering Support and Design Assistance

Look for a CNC partner that does more than just cut metal or plastic. Chienfu offers:

- Design for Manufacturability (DFM): Our engineers collaborate with you early in the development cycle to refine part geometry, select optimal materials, and identify cost-saving opportunities.

- Rapid Prototyping: Speed is crucial in modern product development. We can turn around prototypes quickly, helping you test and iterate designs before committing to full-scale production.

- Comprehensive Services: From post-processing (anodizing, plating, laser engraving) to final assembly and packaging, a one-stop solution reduces logistical complexity.

Production Capacity and Lead Times

Time-to-market pressures mean you can’t afford unexpected delays. Ensure your CNC partner can scale production and meet deadlines:

- Flexible Lot Sizes: Whether you need a small pilot run or millions of parts per year, the manufacturer should accommodate variable order volumes without compromising quality.

- Dedicated Project Management: A single point of contact helps coordinate scheduling, ensures transparency, and tackles issues before they become bottlenecks.

- Supply Chain Integration: Proximity to reliable raw material suppliers and freight partners can prevent stock-outs or customs-related hold-ups.

Industry Reputation and Testimonials

References from existing clients—especially those in your sector—can provide invaluable insight into a manufacturer’s performance. Satisfied customers reflect a shop’s ability to deliver on promises, maintain consistent quality, and handle the inevitable challenges of production.

Contact Us

Chienfu is committed to delivering Custom Swiss Screw Machine Part solutions tailored to the unique needs of yours . With over four decades of CNC manufacturing expertise and multiple ISO certifications(ISO 9001, QC080000, ISO 14001, ISO 13485), we stand ready to help you overcome your most demanding engineering challenges. Our team of seasoned professionals is dedicated to:

- Streamlining your supply chain with full-service manufacturing—design, machining, finishing, and assembly under one roof.

- Providing transparent, responsive communication throughout every project phase.

- Exceeding quality benchmarks for intricate swiss machine parts used in medical devices, aerospace assemblies, automotive systems, and advanced electronics.